Instrument Panel Production Process

-

1

Core Sub

Attach a pad to the main core to prevent leakage during foaming, and assemble spring nuts and passenger airbag.

-

2

Vacuum Forming

After preheating the skin sheet, apply vacuum suction forming and cooling to skin mold in order to produce half-finished skin products.

-

3

Mechanical Scoring

Set the half-finished skin product to jig and apply vacuum suction, and form a tear line of passenger airbag by using mechanical scoring equipment.

-

4

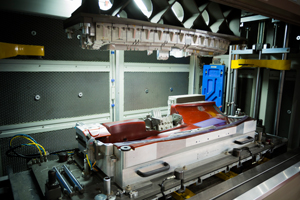

Foaming

Set the half-finished skin product and main core to foaming mold and inject polyurethane generated by addition of polyol and isocyanate to produce half-finished foaming product.

-

5

Trimming

Remove unnecessary parts of the half-finished foaming product by using the water jet robot system.

-

6

Hot Knife Scoring

Form a tear line of passenger airbag on the polyurethane layer and panel of the half-finished foaming product by using a hot knife.

-

7

Ultrasonic Welding

Weld the instrument panel to the upper panel with a frictional heat generated between the two products to produce a half-finished product.

-

8

Vibration Welding

Weld the main panel to the defroster nozzle with a frictional heat between the two products, generated by vibration, to produce a half-finished product.

Cockpit Module Assembly process

-

1

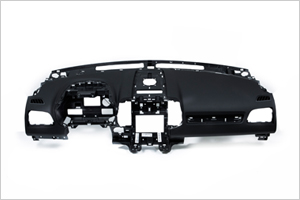

Instrument Panel (IP) finished product

Assemble parts such as a main defroster nozzle and passenger airbag module to the instrument panel.

-

2

Cowl Cross Bar & main wiring

Fix the main wiring appropriately on the Cowl Cross Bar, assemble electronic units such as Body Control Module, Smart Key Module, and Fuse Box, and connect them to the main wiring.

-

3

Cluster assembly

Assemble electronic units such as combimeter, multifunction, and contact coil, and cluster fascia.

-

4

Audio assembly

Assemble audio and switch parts of center part.

-

5

FASCIA assembly

Assemble air vent at center and side, Fascia, and instrument panel.

-

6

Finished module products

Complete the assembly process.

-

7

Exterior inspection

Inspect the exterior condition and operational status for the assembled products.

-

8

Inspection of electronic parts

Perform current carrying and function tests for electronic parts by using ECOS.

-

9

Inspection of finished parts

Inspect the exterior status and wring alignment before shipment.

-

10

Waiting for shipment

Arrange and load the products of which assembly and inspection are completed, in the customer order.

-

11

Shipment

Deliver the products to the customer.

Door trim production process

-

1

Injection forming process

Form thermoplastic materials into products including door panels and center panels.

-

2

Application of bond

Apply bond on the panel surface with a robot to adhere the skin to the door panel.

-

3

Vacuum compression

After the bond is completely applied, compress and adhere the skin to the door pane.

-

4

Trimming

Eliminate the unnecessary parts of the adhesion-finished product.

-

5

Wrapping

Wrap the skin of the cutting-finished product.

-

6

Hot air welding

After temporary assembly of plastic material parts, melt the boss area with hot air and apply pressure for forming.

-

7

Assembly

Assemble parts such as the power window switch, armrest, door pocket, and speaker.

-

8

Thread inspection

Perform current carrying inspection and thread inspection for door trim by using thread inspection equipment.

Console assembly process

-

1

Console assembly

Assemble electronic parts and wiring in the main panels and bracket area.

-

2

Exterior inspection

Check exterior of the assembled parts and operational power.

-

3

Shipment

After assembly and inspection, load the products in the order of customer for delivery.